Probing & Tool Measurement Systems For Machine Tools

Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.

Machine tool probing and on-machine tool measurement is an established best practice in the machining industry. Manually setting and inspecting tools and parts can be detrimental to machining performance and profitability. Our probing and tool setting systems help manufacturers to reduce scrap rates, eliminate machine down-time, and improve component quality.

Our solutions enable automated component set-up, in-cycle gauging, tool setting, and broken tool detection. When coupled with automatic offset updates, our technology enables you to machine with confidence, reduce set‑up times, and improve process control.

Tool Setters & Broken Tool Detectors

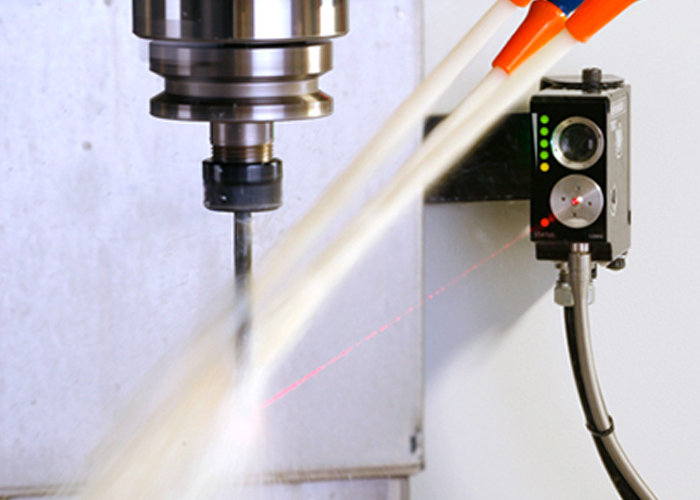

Achieve precise and efficient CNC machining with our automated on-machine tool setters and broken tool detectors. Explore our range of contact and non-contact solutions for CNC machines.

Probes for Workpiece Set‑up & Inspection

Explore our range of touch-trigger and scanning probes for workpiece set-up and inspection.

Tool Setters & Broken

Tool Detectors

Discover our tool setting and broken tool detection systems for all types and sizes of CNC machine tools.

Probing & Tool

Setting Software

Maximise your probing and tool setting hardware with our flexible macro and PC-based software and apps.

Machine Tool Diagnostics

Discover our machine tool maintenance and health check monitoring solutions for reliable, productive machining.

Enclosed Optical Encoders

Designed to withstand harsh environments, find your enclosed optical encoder solution for machine tool applications.

Support Library

Visit our technical support library for help with installation and training on machine tool hardware and software products.

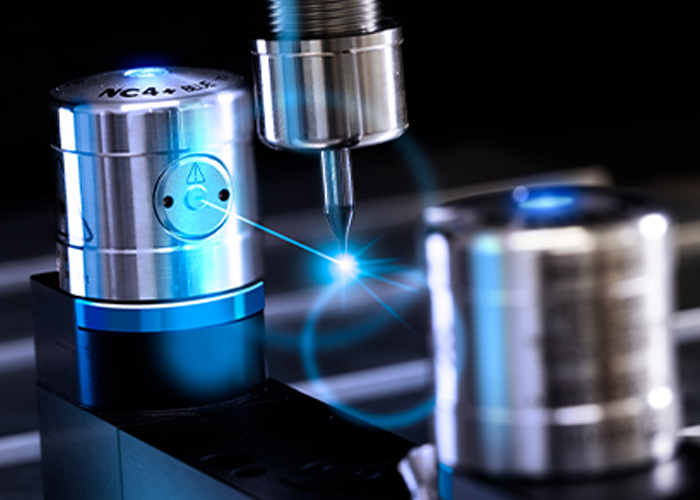

Advance Laser Tool Setters

Explore our advanced laser tool setters to set tools, detect chipped edges, monitor run-out, inspect complex profiles, all without the risk of tool damage during measurement.

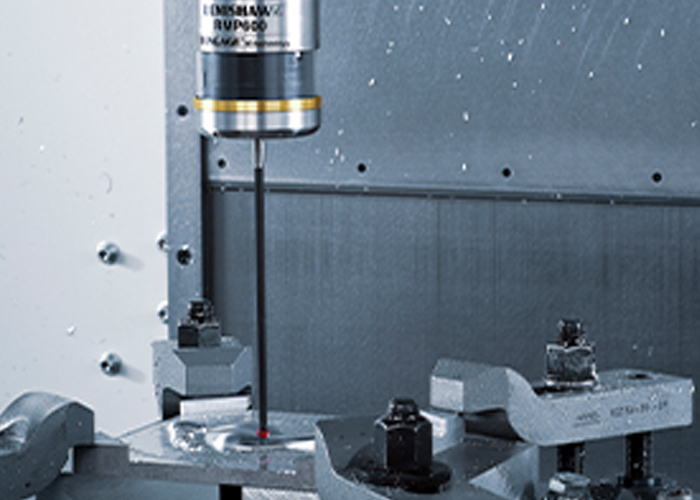

Contact Tool

Setters

Discover our contact tool setters for tactile tool setting and broken tool detection. With a choice of transmission technology to suit your application.

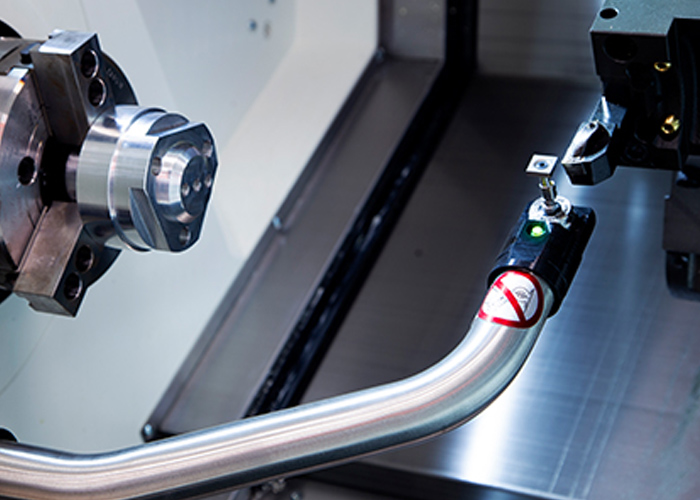

Tool

Setting

Arms

Discover our high-precision arms for tool and workpiece measurement, designed for 2-axis and 3-axis CNC machines.

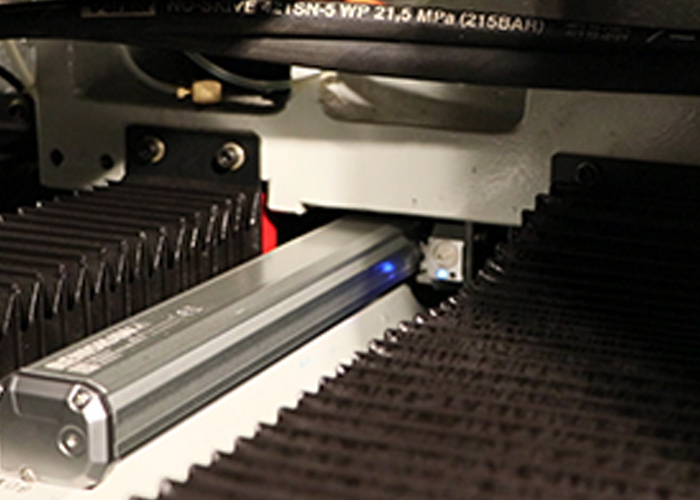

Broken Tool

Detection

System

Learn about our high-speed, non-contact laser broken tool detection system. Ideal for applications when cycle time is critical.